Quality measurement

DiaBeadsTM always supplies our valuable customers with world-class products, confirmed by the reliable Total Quality Management system.

The most important of our quality guarantees is the trustworthy wear-rate, compression strength tested to provide maximum efficiency to customers in the field.

Compression Strength Testing

1 The result of our DiaBeadsTM testing showed as kgf/mm2.

- - if the size “mm” is input, mm2 is calculated automatically by the computer.

- - As the result, the standard size of each product is the same.

2 Three step checking : 20~100 pieces per time

- - First : pre-sintering (choose sintering or recycling)

- - Second : post-sintering (compare with the result of pre-sintering)

- - Third : final check after separation of roundness

3 Testing Machine

- - universal compression strength machine

- - max kgf : 1000kgf

- - model : NA-1000 (Nanotech, Korea)

- - zig : polished surface zig of Si3N4 Materials

- - automatic control and display by computer

- - test head speed : 5~10mm / min.

Wear Rate Testing Compression Strength Testing

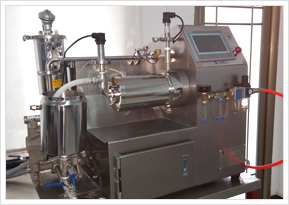

1 1L Vessel Volume Test Grinding Machine

2 Horizontal Type : SM 108 (Wuxi Xin Guang, China)

- - agitator : disc (zirconia) type

- - tested for smaller size than 2.0mm

- - tip speed : 15m/sec

3 Vertical Type : PE 075 (Netzsch, Germany)

- - agitator : disc (zirconia) type

- - tested for bigger size than 2.0mm

- - tip speed : 10m/sec

4 Quality analysis test method

- - charge volume : 50ml water + 500ml beads

- - time : 4~8hrs